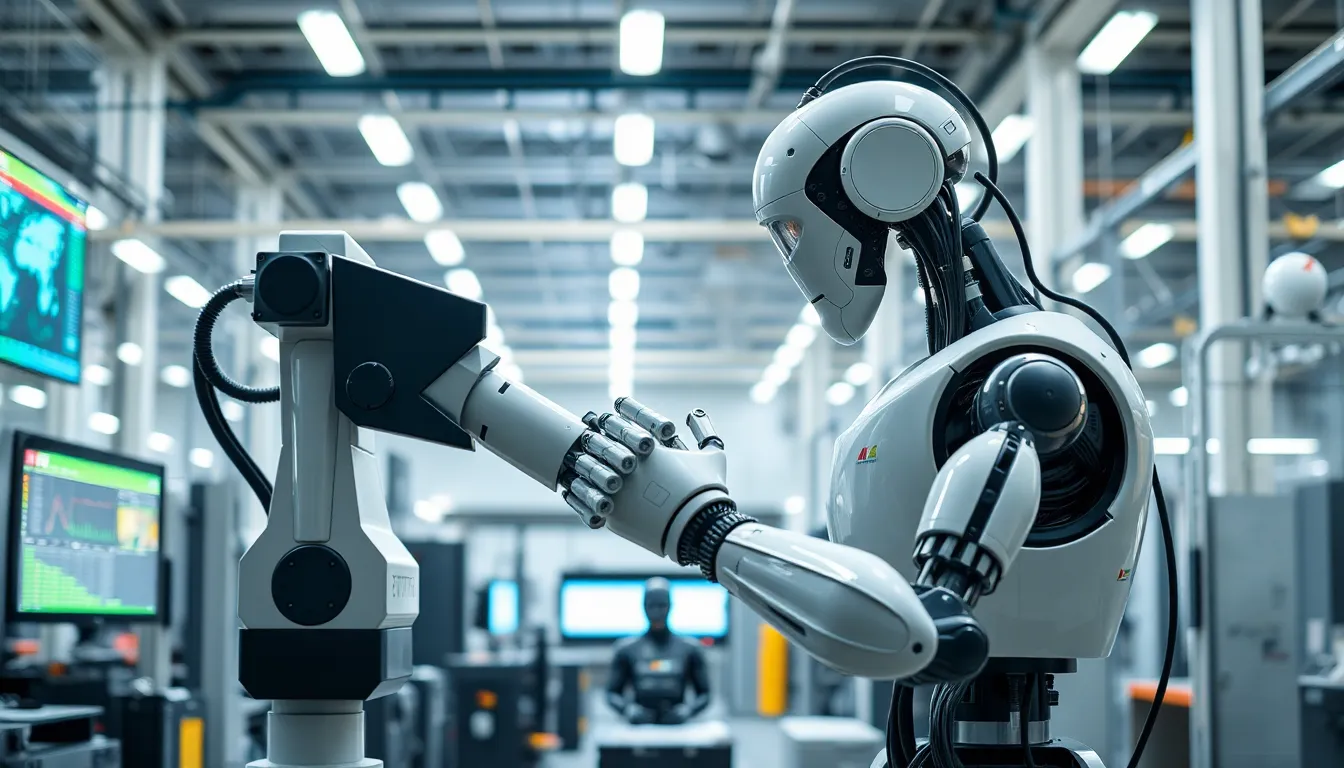

Imagine a world where robots don’t just follow commands but actually chat with each other about their favorite tasks. Welcome to the fascinating realm of IoT for robotics, where connectivity transforms machines into smart, collaborative partners. It’s not just about shiny gadgets anymore; it’s about creating a network of intelligent devices that can think, learn, and adapt.

Table of Contents

ToggleOverview of IoT for Robotics

IoT integration significantly enhances robotics capabilities. It allows robots to access and exchange data with other machines in real-time. Increased connectivity results in improved cooperation among robots, enabling them to complete complex tasks more efficiently.

Data collection and analysis play critical roles in IoT for robotics. Sensors embedded in robots gather valuable information about their environment. This information aids robotic decision-making, allowing for adaptive responses to changing conditions.

Remote monitoring becomes feasible through IoT technologies. Operators can oversee robotic systems from a distance, ensuring optimal operations without needing to be physically present. This aspect reduces downtime and enhances productivity in various sectors.

The synergy between cloud computing and robotics accelerates processing power. Cloud platforms store and analyze vast amounts of data, facilitating advanced computational tasks. Such capabilities empower robots to undertake more complex operations that exceed local processing limits.

Security is a crucial consideration in IoT for robotics. With increased connectivity comes the risk of cyber threats. Implementing robust security measures safeguards sensitive data and ensures reliable robot performance.

Industry applications reflect the diversity of IoT in robotics. Manufacturing facilities utilize connected robots for assembly lines. In healthcare, robotic systems assist in surgeries and patient care, showcasing the versatility afforded by IoT technologies.

Overall, IoT enhances robotic functionality, driving advancements across various fields. Intelligent robots not only perform predefined tasks but also adapt to their environments, forming a cornerstone of modern automation.

Benefits of IoT in Robotics

IoT integration delivers significant advantages to robotics, enhancing functionality and efficiency across various applications.

Enhanced Connectivity

Enhanced connectivity transforms robots into collaborative entities. Through IoT networks, they share information in real-time, significantly increasing task effectiveness. For example, machines can quickly update each other about environmental changes, optimizing their responses. Connected robots streamline processes in manufacturing environments, coordinating movements and minimizing errors. The ability to communicate with other devices allows for seamless interaction, promoting teamwork among robots. This interconnected framework creates smarter, more agile robotic systems that respond dynamically to their surroundings.

Real-Time Data Processing

Real-time data processing plays a vital role in robotic performance. With IoT, sensors collect vast amounts of data continuously. This data supports immediate decision-making, allowing robots to adapt quickly without human intervention. For instance, robots in healthcare can analyze patient information almost instantly, enhancing care quality. Additionally, the cloud’s processing capabilities enable advanced analysis, facilitating complex tasks like predictive maintenance. Real-time insights contribute to significant reductions in operational downtime. Robots, when equipped to process information on the fly, ultimately become more effective and reliable in various applications.

Applications of IoT in Robotics

IoT integration revolutionizes robotic capabilities across various sectors. Real-time data sharing enhances effectiveness and collaboration among robots in different environments.

Industrial Automation

Industrial automation thrives with IoT-enabled robots. These robots monitor production lines, collecting data on productivity and equipment performance. Enhanced connectivity allows for immediate adjustments during manufacturing processes, reducing errors and downtime. As data flows between machines, predictive maintenance becomes possible, identifying issues before they escalate. Such capabilities boost efficiency and streamline operations in industries like automotive and electronics. Specific examples include assembly robots that adapt their tasks based on sensor feedback, creating a dynamic production environment.

Smart Home Robots

Smart home robots illustrate the potential of IoT in everyday life. These devices communicate with smart home systems, facilitating tasks like cleaning, security monitoring, and energy management. They operate autonomously, adjusting their actions based on real-time environmental data. For instance, a robotic vacuum navigates rooms intelligently, avoiding obstacles while optimizing cleaning patterns. Home security robots provide round-the-clock surveillance, alerting homeowners to unusual activity. The ability to manage these devices remotely through mobile apps enhances user convenience, showcasing how IoT transforms household tasks into seamless, integrated experiences.

Challenges Faced in IoT for Robotics

Integrating IoT into robotics faces several challenges that hinder optimal performance and widespread adoption.

Security Concerns

Security concerns arise from increased connectivity in IoT-enabled robotics. Cyber threats target vulnerabilities in communication channels, risking data breaches and unauthorized access. Protecting sensitive information requires robust encryption methods and secure authentication processes. Regular security audits and updates are essential to safeguard systems against emerging threats. Furthermore, implementing intrusion detection systems can help identify and mitigate risks in real time. Overall, addressing security concerns is vital for building trust and ensuring safe operations within IoT-driven robotics.

Integration Issues

Integration issues complicate the seamless adoption of IoT in robotics. Different communication protocols often hinder compatibility among devices, creating communication barriers. Standardizing protocols can promote interoperability, allowing diverse robots and systems to work together effectively. Data processing and management also present challenges, as variations in data formats impact analysis and responsiveness. Ensuring devices can process and understand shared information is crucial for achieving real-time cooperation. Overall, resolving integration issues is key to maximizing the benefits of IoT in robotics applications.

Future Trends in IoT for Robotics

Emerging trends indicate significant advancements in IoT for robotics, shaping a dynamic future. Enhanced capabilities stem from two key developments: artificial intelligence and 5G technology.

Advancements in AI and Machine Learning

Transformative improvements in artificial intelligence and machine learning are accelerating robotic autonomy. Intelligent algorithms enable machines to learn from experience, thus optimizing performance through data-driven insights. Adaptive learning helps robots adjust to fluctuating environments, ensuring efficient task execution. Real-time analytics enhance decision-making processes, making robots more responsive and alert. A prime example includes robots in manufacturing that analyze production data, adapting processes to enhance output quality. These advancements underscore the shift toward smarter, more autonomous robotic systems equipped to navigate complex scenarios.

Expansion of 5G Technology

Rapid expansion of 5G technology significantly enhances IoT capabilities for robotics. Increased bandwidth and lower latency facilitate seamless communication between devices. Robots, equipped with 5G connections, can transmit and receive data instantaneously, improving real-time operational efficiency. Applications such as remote diagnostics and control become more practical, empowering operators to manage robotic systems from distances. Enhanced connectivity supports complex applications, including autonomous vehicles and smart factory workflows. As industries integrate 5G, the potential for robotics grows, leading to more innovative solutions in diverse sectors.

Conclusion

The integration of IoT in robotics is paving the way for a new era of intelligent automation. As robots become more connected and capable of real-time communication, their ability to collaborate and adapt transforms various industries. This evolution not only enhances efficiency but also improves the quality of services in sectors like healthcare and manufacturing.

While challenges such as security and compatibility persist, ongoing advancements in AI and 5G technology promise to overcome these obstacles. The future holds immense potential for IoT-enabled robots to revolutionize everyday tasks and complex operations alike. Embracing this technology will be crucial for businesses aiming to stay competitive in an increasingly automated world.